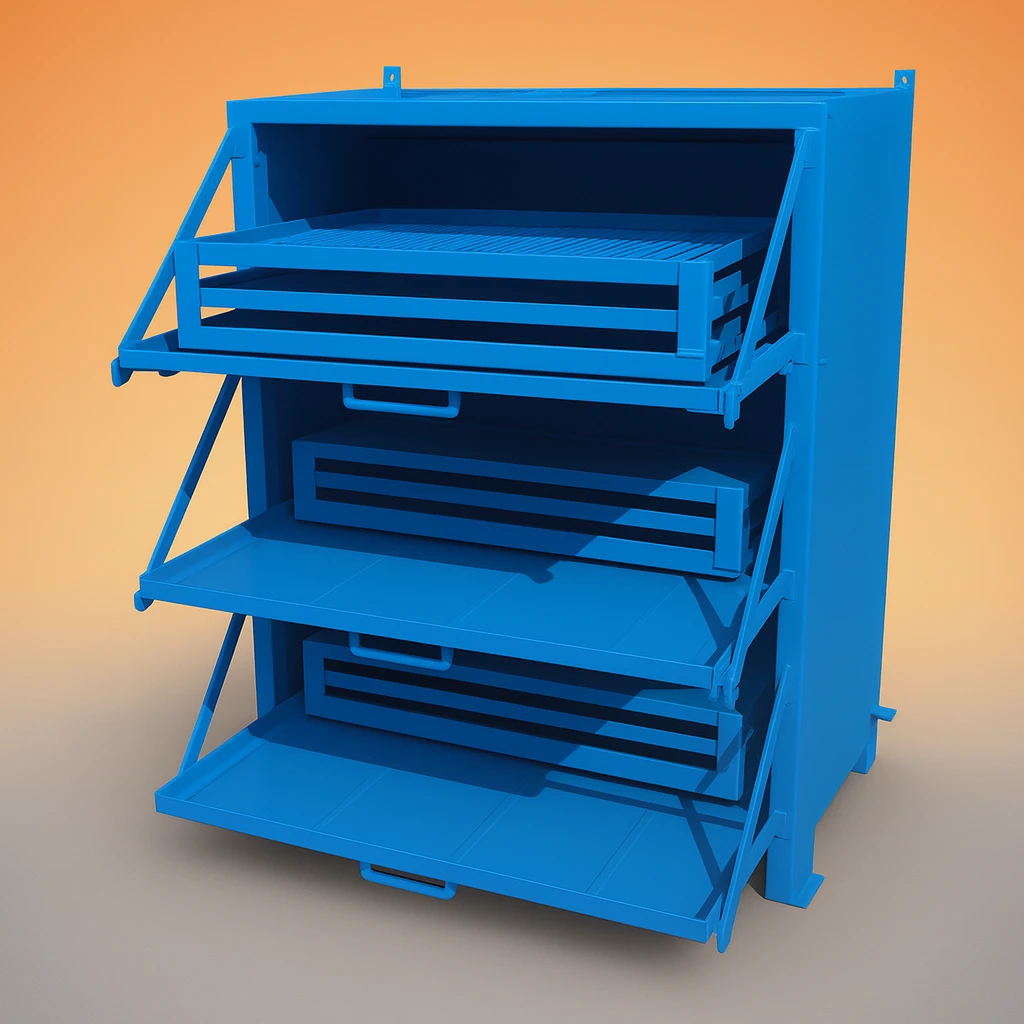

Work & Inspection Tables Manufacturer in Pune

Sunex makes work & inspection tables that are built to last in tough industrial settings where precision, ergonomics, durability, and operator efficiency are very important. These tables are used in the automotive, HVAC, appliances, engineering, FMCG, and general manufacturing industries for assembly lines, QA/QC inspections, component verification, measuring stations, and tool layout operations. Sunex workstations are made using MS IS2062 steel frameworks, HDPE/wooden/ESD tabletops, and ergonomic design concepts. They provide solid working surfaces, accurate dimensional checks, and long-lasting performance in production applications.

- Powder-coated to protect against rust, oil, grease, and constant use

- Keeps measuring tools, gauges, and inspection fixtures accurate.

Advantages

Why Our Work & Inspection Tables Work Better:

Made from IS-grade structural steel

Makes sure that it is strong and lasts a long time.

Compliance with global standards

EN + OSHA ergonomics + production that meets ISO standards.

Made to be done again and again

A stable place for tools, gauges, fixtures, and inspection tools.

Technical Specifications & Applications

uses :

3. MIG welding to evenly distribute weight

4. Ribs that help reduce vibrations

3. ESD Laminated Top: For electronics and parts that are sensitive

4. SS304 Top: For situations where hygiene is very important or where chemicals are present

5. The thickness depends on the job (usually 12–25mm).

3. Optional PU or zinc coating for chemical exposure

3. Works with both 2D and 3D fixtures

4. Side panels and tool organisers

5. Storage under the shelf

6. Providing lighting (optional)

7. Pads that stop vibration

3. Putting together the needs of the end user

3.MIG welding

4.Machining on a table (HDPE/wood/ESD)

3. Polishing SS (if the top is stainless)

2.Test for flatness on the surface

3. Validation of ergonomics