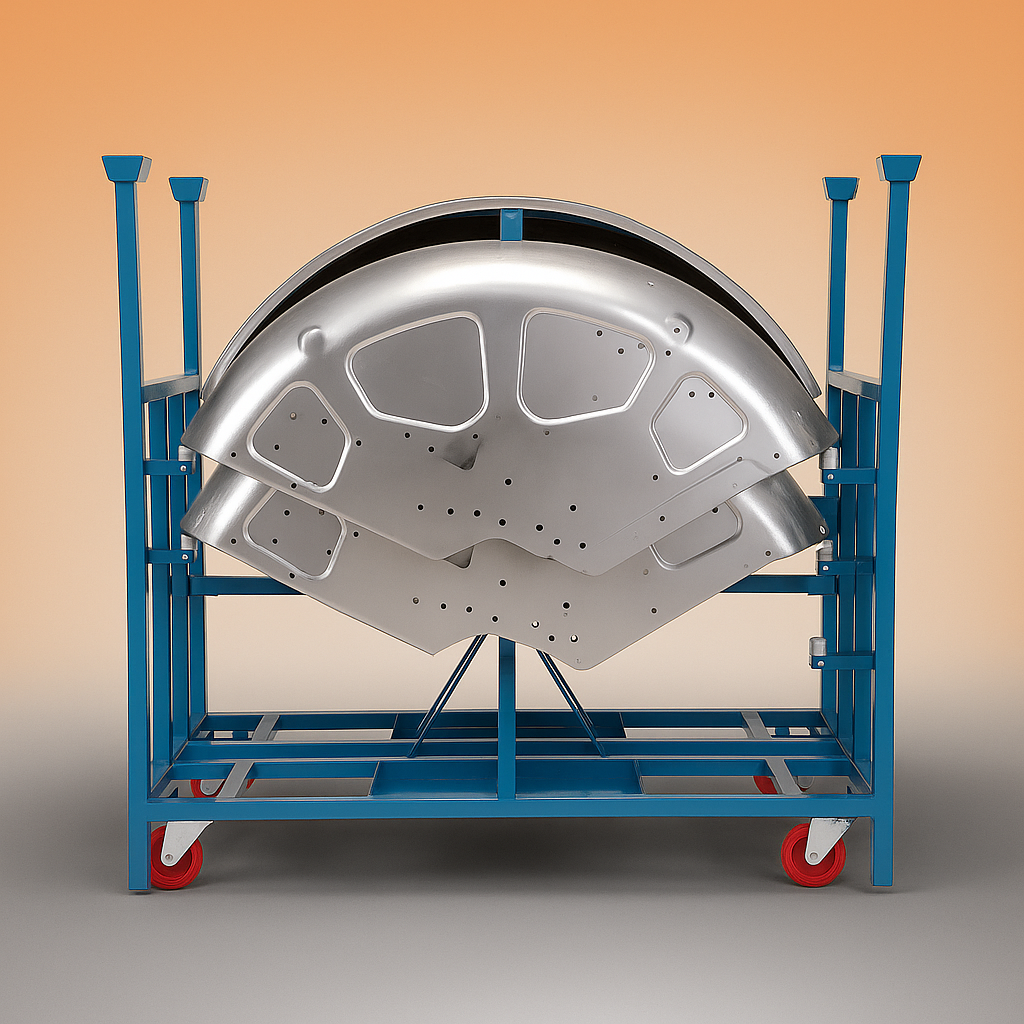

Logistic Trolleys & Pallets for Industrial Material Handling

Sunex makes heavy-duty logistic trolleys and pallets that are designed to safely, quickly, and consistently transport parts in the sectors of automotive, HVAC, FMCG, electronics, agricultural machinery, and general engineering. Each unit has safety features that satisfy industry standards, as well as the best manner to disperse loads and make it easy to use. This is fantastic for OEM production lines, moving products throughout the plant, and factory logistics staff that work inside. Our factory that makes our trolleys and pallets is ISO 9001:2015 certified. They employ their skills in creating steel parts, welding accurately, and making parts for specific functions to keep operations running as smoothly as possible and keep parts from getting damaged.

- Quality Control System

- Building Quality Industrial

Welcome to Industrie, a leading industry innovator with a rich history of excellence with a passion make also for precision we have been empowering industries and driving progress for

- Quality Control System

- Building Quality Industrial

Welcome to Industrie, a leading industry innovator with a rich history of excellence with a passion make also for precision we have been empowering industries and driving progress for

- Quality Control System

- Building Quality Industrial

Why Our Trolleys and Pallets Are Better:

Higher Durability

Adding strength to the structure during long durations of useCoatings that don't rust or wear away during the making Stable movement when loads are repeated.

Unique Designs

ach pallet or cart is made to fit a certain part for a customer.Custom supports, nests, fittings, trays, and profiles Movement paths (WIP, line feed, and storage)

Accuracy of OEM Grade

Make loads for specified uses Works with lines of assembly Dimensional accuracy that can be repeated Making and designing tools in-house Making prototyping.

Technical Specifications & Applications

Technical Specifications :

2. More protection for corners and edges

3. A coating that keeps things from rusting on a large scale

4. Making the handle and movement feel good

5. Base that works with stackers and forklifts for pallets

2. Medium Duty: Great for HVAC units, assemblies, and parts that go together.

3. Heavy Duty: Made for engines, radiators, big parts, and metal parts

4. It has the proper amount of room for each use.

2. A mix of fixed and swivel wheels lets you move things around easily.

3. Moving about the shop floors with little noise

2. OSHA Manual Handling Guidelines — Ergonomic and safety alignment

3. ISO 9001:2015 —Quality management and consistency

2. Machined parts, trims, plastic components

3.Engine line-feed pallets and bin movements

2. Returnable movement trolleys for fragile components

2. Controlled internal transport

2.Jig/fixture handling

3. Line-side component feeding